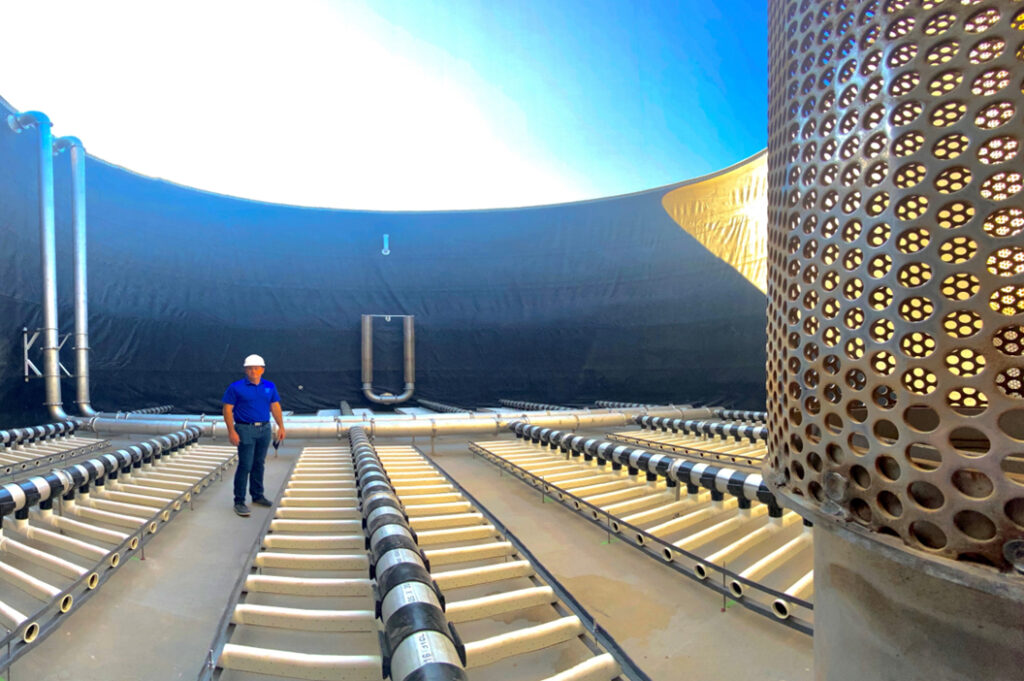

Blue Whale Technologies has decades of experience of sizing and designing MBBR systems for the treatment of industrial and municipal wastewater treatment systems. Blue Whale has a unique blend of experience and expertise focusing on industrial wastewater streams applying multi-stage MBBR technology designed for BOD/COD reduction, Nitrification of ammonia and denitrification systems as well. The BlueFAS™ MBBR systems can be designed for new plants and for the retrofit and upgrade of existing plants to provide compact operator friendly solutions. We can also combine them with NanOH-PURE™ Ultrafine bubble systems, otherwise known as nanobubble systems, and BluePULSE™ Electro-Oxidation systems to provide the most compact and efficient systems in the industry.

MBBR PROCESS DESCRIPTION

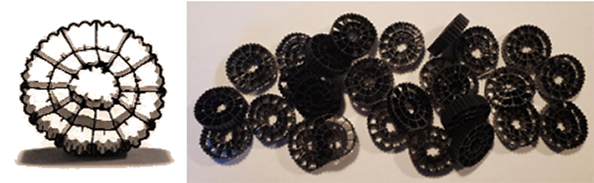

The MBBR Bioreactors are loaded with neutrally buoyant biofilm carriers to provide a process resilient high surface area substrate material for the growth of a diverse community of microorganisms.

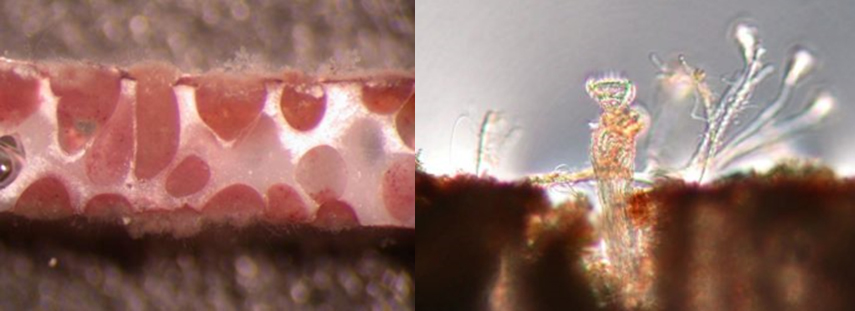

The attached growth media has a very high surface-to-volume ratio, allowing for a high concentration of biological growth to thrive within the internally protected surface areas. Media types are typically in the specific gravity range of 0.96 – 0.98 to allow the media to become neutrally buoyant with the biofilm attached. The fill fraction of the B-1 MBBR media can be 25% v/v up to 70% v/v depending on the application parameters. BlueFAS MBBR Systems can be sized and designed to provide the capabilities of adding MBBR media to the MBBR Bioreactors to accommodate future growth.

Applications

The MBBR media is completely mixed within the MBBR Bioreactors with diffused air for aerobic treatment processes such as COD/BOD reduction and nitrification of ammonia. For anoxic MBBR Bioreactors low speed submersible mechanical mixers are used for denitrification systems. The MBBR media undergoes thousands of collisions per second to slough dead biomass to expose the biofilm to the organic load. This continuous sloughing action provides a high rate attached-growth biofilm treatment process that treats wastewater in a fraction of the space typically required by a conventional activated sludge process.

The sloughed biomass becomes suspended within BlueFAS™ MBBR Bioreactor and eventually flows through the MBBR retention screen with the treated wastewater and directed to a Secondary DAF System or clarifier for TSS clarification & removal.

removal.

Process Benefits & Advantages

- Ease of Operation: The single pass BlueFAS™ MBBR treatment process is easy to operate and maintain since DO is the only process parameters that need to be monitored/adjusted.

- Compact Process: The BlueFAS™ MBBR process will typically require a fraction the space of an activated sludge process treating equivalent loads.

- Responds to Load Fluctuations without Operator Intervention: Self-regulating nature of biofilm adjusts to variations in process load. As the contaminant load increases, the microbial population in the biofilm increases enabling additional treatment capacity. Likewise, during low loading conditions, the population self-adjusts and decreases. This eliminates the need to return a dilute return activated sludge stream and alleviates the requirements for continual adjustments associated with a suspended growth system.

- Minimal maintenance associated with the MBBR Bioreactor

- Future process expansion is accommodated by simply adding MBBR media and increasing the air volume for increased organic loading conditions.

Applications

Blue Whale provide portable MBBR systems known as BioBox™ MBBR Systems to provided compact treatment processes that are deployable for rapid system installation and operation. The BioBox™ MBBR systems are modular in design for ease of transportation to the project site. They can then be configured in multiple stages and parallel configurations for redundancy purposes. For high load applications, they can be stacked with side wall extensions to increase process side wall depth.